Technical and sales office

The technical office, staffed by expert personnel in the sector and available to the clientele, constantly seeks new technical solutions with the customer every day.

Cutting/drilling and bending aluminium sections

Cutting/drilling and bending aluminium sections

The cutting and drilling operations on sections takes place using automatic shearing machines, managed by software, in order to optimize and manage orders as quickly as possible.

Bending the sections used by Alunova guarantees the highest quality of the aluminium product for the end-user, as well as the possibility of handling virtually all shapes and types.

Welding and mechanical assembly

Welding and mechanical assembly

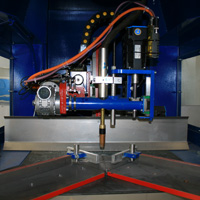

Welding the aluminium profiles, for the painted frames series, is carried out using completely robotized machinery of the latest generation.

Mechanical assembly, with punching of the bracket details, takes place mainly with a "wood-like" finish, but the same system can also use painted sections.

Painting and decorating

Painting and decorating

The Painting and Decoration production lines follow very high standards in compliance with the standards in force in Environmental and Security terms.

Alunova therefore avails itself of the best partners in the painting field currently in the aluminium sections market.

Logistics

Logistics

The shipments and packaging are managed completely by internal company personnel with the use of pallets for distributing large batches or of wooden crates specially made for each shipment.